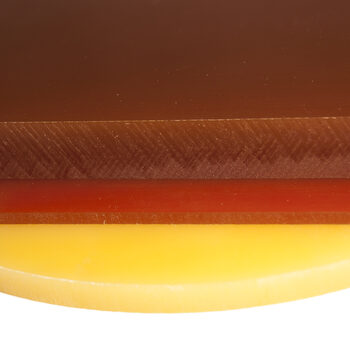

WKL Polyurethane is available in sheets of 3000x500mm each or in rounds.

This material has different characteristics such as:

- Abrasion resistance

- Resilience

- Resilience to compression

- Resistance to temperatures, both cold and hot, not exceeding 100 °C

- Water resistance

- Mechanical properties, thanks to its low friction coefficient, polyurethane lends itself to being cut, turned, sawn or glued

- Insulating properties

Possibility of creating customized products.

PLATES |

|

Thickness(mm) |

Minimum weight(kg) |

1,0 ± 0,2 |

1,560 |

1,5 ± 0,2 |

2,540 |

2,0 ± 0,2 |

3,520 |

3,0 ± 0,3 |

5,280 |

4,0 ± 0,3 |

7,240 |

5,0 ± 0,3 |

9,190 |

6,0 ± 0,3 |

11,150 |

7,0 ± 0,4 |

13,200 |

8,0 ± 0,4 |

14,870 |

9,0 ± 0,4 |

17,840 |

10,0 ± 0,4 |

18,780 |

12,0 ± 0,4 |

22,700 |

15,0 ± 0,5 |

28,370 |

18,0 ± 0,5 |

34,240 |

20,0 ± 0,5 |

38,160 |

BAR |

||

Diameters and tolerances (mm) |

Minimum weight (kg) |

Length (mm) |

15 ± 0,3 |

0,110 |

500 |

20 ± 0,3 |

0,190 |

500 |

25 ± 0,3 |

0,300 |

500 |

30 ± 0,3 |

0,430 |

500 |

35 ± 0,4 |

0,590 |

500 |

40 ± 0,4 |

0,750 |

500 |

45 ± 0,4 |

0,980 |

300 |

50 ± 0,4 |

1,200 |

500 |

55 ± 0,5 |

1,470 |

500 |

60 ± 0,5 |

1,740 |

500 |

70 ± 0,5 |

2,370 |

500 |

80 ± 0,5 |

3,090 |

500 |

90 ± 0,5 |

3,970 |

500 |

100 ± 0,5 |

4,850 |

500 |

120 ± 1,0 |

6,920 |

300 |

150 ± 1,0 |

10,800 |

500 |

180 ± 1,0 |

15,500 |

300 |

200 ± 1,0 |

19,200 |

170 |

Characteristics |

Name |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

Hardness Sh A |

ASTM D 2240 |

57 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

Density gr/cm³ |

DIN 53475 |

1,24 |

1,24 |

1,25 |

1,25 |

1,25 |

1,25 |

1,25 |

1,26 |

Elongation % |

ASTM D 412 C |

700 |

650 |

620 |

600 |

550 |

550 |

500 |

480 |

Load at break kg/cm² |

ASTM D 412 C |

280 |

300 |

330 |

350 |

370 |

390 |

400 |

420 |

Resistance to tearing Kg/cm |

ASTM D 624 B |

50 |

60 |

70 |

80 |

85 |

90 |

95 |

100 |

Abrasion mm³ |

DIN 53516 |

55 |

50 |

48 |

48 |

48 |

46 |

44 |

42 |

Resilience |

ASTM D 945 |

46 |

47 |

47 |

48 |

48 |

50 |

51 |

52 |

Permanent deformation 70 h t.a. |

ASTM D 395 B |

10 |

10,5 |

10 |

11 |

12 |

12 |

13 |

12 |

Permanent deformation 22 h A 70°C |

ASTM D 395 B |

22 |

23 |

24 |

25 |

25 |

26 |

26 |

26 |